nylon abs pp pom abs plastic rod factory

There are thousands of plastics on the market for rapid prototyping or small-scale production – choosing the right plastic for a particular project can be overwhelming, especially for aspiring inventors or aspiring entrepreneurs. Each material represents a compromise in terms of cost, strength, flexibility and surface finish. It is necessary to consider not only the application of the part or product, but also the environment in which it will be used.

In general, engineering plastics have improved mechanical properties that provide greater durability and do not change during the manufacturing process. Some types of plastics can also be modified to improve their strength, as well as impact and heat resistance. Let’s dive into the different plastic materials to consider depending on the functionality of the final part or product.

One of the most common resins used to make mechanical parts is nylon, also known as polyamide (PA). When polyamide is mixed with molybdenum, it has a smooth surface for easy movement. However, nylon-on-nylon gears are not recommended because, like plastics, they tend to stick together. PA has high wear and abrasion resistance, and good mechanical properties at high temperatures. Nylon is an ideal material for 3D printing with plastic, but it absorbs water over time.

Polyoxymethylene (POM) is also an excellent choice for mechanical parts. POM is an acetal resin used to make DuPont’s Delrin, a valuable plastic used in gears, screws, wheels and more. POM has high flexural and tensile strength, rigidity and hardness. However, POM is degraded by alkali, chlorine and hot water, and is difficult to stick together.

If your project is some kind of container, polypropylene (PP) is the best choice. Polypropylene is used in food storage containers because it is heat resistant, impervious to oils and solvents, and does not release chemicals, making it safe to eat. Polypropylene also has an excellent balance of stiffness and impact strength, making it easy to make loops that can be bent repeatedly without breaking. It can also be used in pipes and hoses.

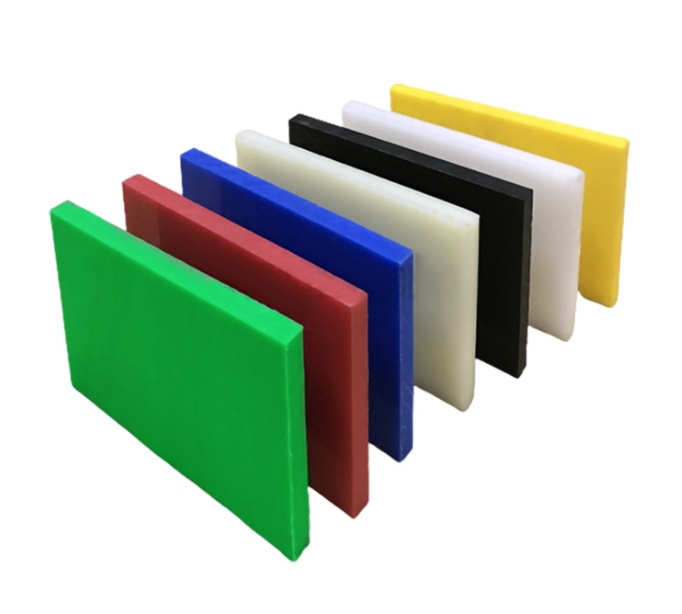

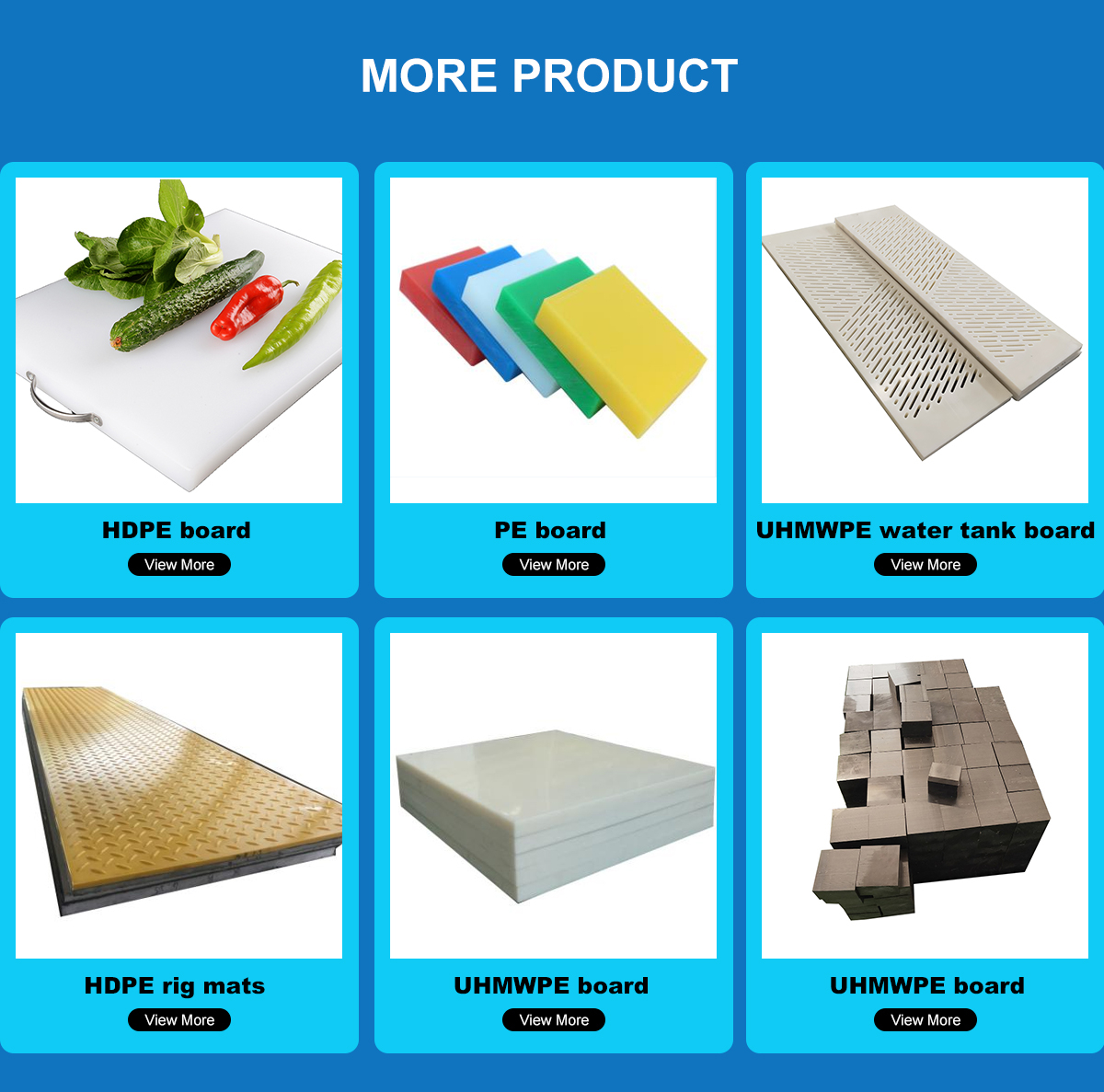

Another option is polyethylene (PE). PE is the most common plastic in the world with low strength, hardness and stiffness. It is usually a milky white plastic used to make medicine bottles, milk and detergent containers. Polyethylene is highly resistant to a wide range of chemicals but has a low melting point.

Acrylonitrile butadiene styrene (ABS) material is ideal for any project requiring high impact resistance and high tear and fracture resistance. ABS is lightweight and can be reinforced with fiberglass. It is more expensive than styrene, but lasts longer due to its hardness and strength. Fusion-molded ABS 3D modeling for rapid prototyping.

Given its properties, ABS is a good choice for wearables. At Star Rapid, we created the smartwatch case for E3design using injection molded black pre-painted ABS/PC plastic. This choice of material makes the entire device relatively light, while also providing a case that can withstand occasional shocks, such as when the watch hits a hard surface. High impact polystyrene (HIPS) is a good choice if you need a versatile and impact resistant material. This material is suitable for making durable power tool cases and tool cases. Although HIPS are affordable, they are not considered environmentally friendly.

Many projects call for injection molding resins with elasticity like rubber. Thermoplastic polyurethane (TPU) is a good choice because it has many special formulations for high elasticity, low temperature performance and durability. TPU is also used in power tools, rollers, cable insulation, and sporting goods. Due to its solvent resistance, TPU has high abrasion and shear strength and can be used in many industrial environments. However, it is known for absorbing moisture from the atmosphere, making it difficult to process during production. For injection molding, there is thermoplastic rubber (TPR), which is inexpensive and easy to handle, such as for making shock-absorbing rubber grips.

If your part requires clear lenses or windows, acrylic (PMMA) is best. Because of its rigidity and abrasion resistance, this material is used to make shatterproof windows such as plexiglass. PMMA also polishes well, has good tensile strength, and is cost effective for high volume production. However, it is not as impact or chemical resistant as polycarbonate (PC).

If your project requires a stronger material, PC is stronger than PMMA and has excellent optical properties, making it a suitable choice for lenses and bulletproof windows. PC can also be bent and formed at room temperature without breaking. This is useful for prototyping because it does not require expensive mold tools to form. PC is more expensive than acrylic, and prolonged exposure to hot water can release harmful chemicals, so it doesn’t meet food safety standards. Due to its impact and scratch resistance, PC is ideal for a variety of applications. At Star Rapid, we use this material to make housings for Muller Commercial Solutions handheld terminals. The part was CNC machined from a solid block of PC; since it needed to be completely transparent, it was sanded by hand and steam polished.

This is just a brief overview of some of the most commonly used plastics in manufacturing. Most of these can be modified with different glass fibers, UV stabilizers, lubricants or other resins to achieve certain specifications.

Gordon Stiles is the founder and president of Star Rapid, a rapid prototyping, rapid tooling and low volume manufacturing company. Based on his engineering background, Stiles founded Star Rapid in 2005 and under his leadership the company has grown to 250 employees. Star Rapid employs an international team of engineers and technicians who combine cutting-edge technologies such as 3D printing and CNC multi-axis machining with traditional manufacturing techniques and high quality standards. Prior to joining Star Rapid, Styles owned and operated STYLES RPD, the UK’s largest rapid prototyping and tooling company, which was sold to ARRK Europe in 2000.